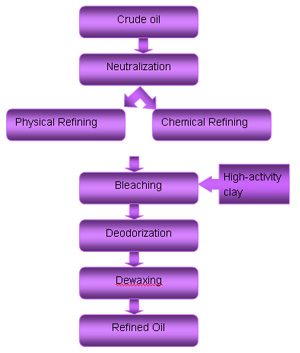

Neutralizing:

The Crude Oil temporarily stored in Crude Oil Tank is pumped

into neutralizing tank by Oil Pump. The oil is mixed with alkali

lye in Mixer and neutralized in Neutralizing Tank, free fatty

acid has been neutralized or saponified to be Soapstock. Neutralizing:

The Crude Oil temporarily stored in Crude Oil Tank is pumped

into neutralizing tank by Oil Pump. The oil is mixed with alkali

lye in Mixer and neutralized in Neutralizing Tank, free fatty

acid has been neutralized or saponified to be Soapstock.

Physical refining: Physical Refining means

removing gum in the oil in process of degumming in special method

and removing the FFA in process of deodorizing by steam. It

has the following features:

1. Less oil loss and high oil refining ratio;

2. No waste water in process of production;

3. More FFA is distilled out;

4. More suitable for oil with high acid value and low gum-impurity.

Chemical Refining: Chemical Refining means

removing FFA in a chemical way (acid-base neutralization). Gum

and soapfoot is separated out by centrifuges. Chemical refining

has following features:

1. Fine Adaptability and less requirement to crude oil quality;

2. Consistent product oil is got;

3. Less clay is added into compared with physical refining.

Oil Refining process can remove phospholipid, FFA, pigment,

off-flavor and other impurities. It includes the following

sections: Oil Dugumming, Oil Deacidifying, Oil Bleaching, Oil Deodorizing

and Oil Dewaxing.

Oil Bleaching: High-activity clay is added into

oil, mix and heat mixture of oil and clay to make the small

particle of pigment absorbed on the crystal of clay. At last

filtering the oil, perfect mechanism, liable performance, well

configured equipment.

Oil Deodorizing:

Most heat of bleached oil is recovered by heat exchangers, the

bleached oil is heated to the process temperature by mineral

oil or high pressure steam and then the oil enters into the

combined deodorizer, the deodorizer is a combined type: the

upper is packing structure, which is used to remove odor components

like FFA, the lower is plate type used for heat bleaching and

making product quality more consistent. Oil coming from the

deodorizer is cooled and stored after series of heat exchange,

volatile like FFA is collected and stored as by products.

Oil Dewaxing:

It can improve oil palatability, so it plays an important

role to the quality of finished oil. At the same time, dewaxing

can improve oil transparency and brightness. At present, winterizing

method is very popular to dewaxing.

Workshop

View

| |

|

Oil Deodorzing |

|

|

|

Oil Bleaching |

|

Oil Dewaxing

and Fraction |

|